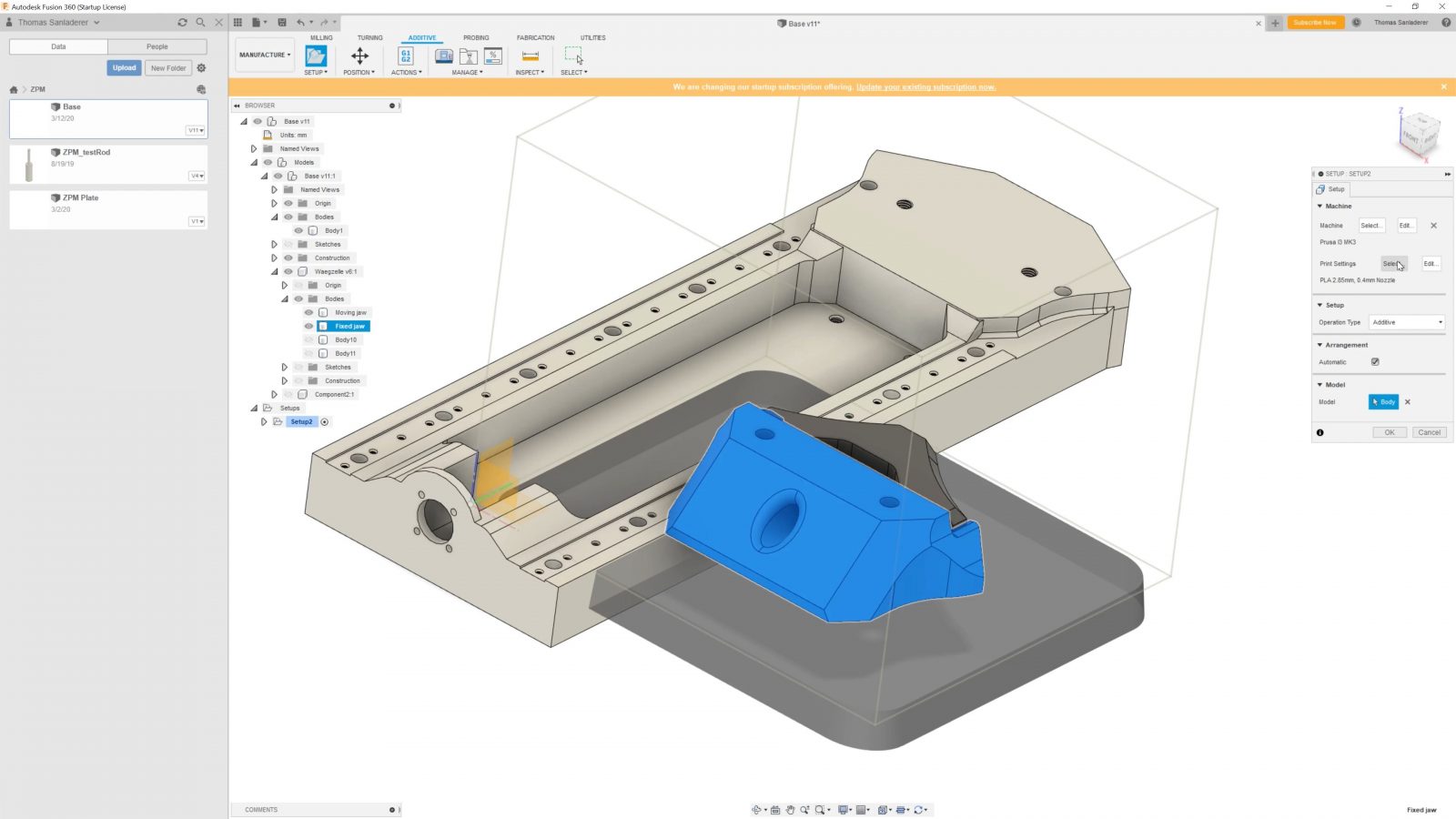

This will vary depending on the machine and what type of outputs you need to tweak before letting the machine spit out parts. The post processing program converts a description of the solid model into a litany of machine movements. For plasma and 2d machining, I use SheetCAM. For CNC, it can be done with a stratospheric commercially-priced SolidWorks or Fusion360 plugin. We need to post-process G code toolpaths (or threedee printing magic) from the solid model to send to the printer or CNC controller. *Don't scale parts.* Redraw them if you have to, but simply setting the driving dimensions one by one and clamping them down is how you get a fully defined 3D part. Everything is derived from this base information.

One, when drawing the dimensions are the king. Okay, another thread I have no business posting in, because I can't find a sustainable use for a threedee printer and all I've got to contribute is 20 years of experience with SolidWorks.

0 kommentar(er)

0 kommentar(er)